|

Fisher

Body - Home

Fisher Body Craftsmanship Goes to War

Fisher Body - Craftsmanship

Fisher Body - Aircraft

Fisher Body - Aircraft

Instruments

Fisher Body - Guns

Fisher Body - Tanks

Fisher Body - Miscellaneous

The Plants

Fisher Body WWII Plant Database

Cleveland Plant #1, OH Plant

Cleveland Plant #2, OH Plant

Detroit Aircraft Unit,

Detroit, MI

Detroit Die and Machine Plant Fleetwood, Detroit, MI Plant

Flint Plant #1, MI Plant

Grand Blanc, MI Tank Arsenal

Grand Rapids, MI Plant

Lansing, MI Plant

Memphis, TN Plant

Ternstedt Manufacturing Division,

Detroit, MI

Grand Blanc Tank Arsenal Built Tanks and Tank Destroyers

Grand Blanc

built M4A2 Sherman Tank Photos

Grand Blanc

Built M4A3 Tank Photos

Grand

Blanc M10 Tank Destroyer Photos

The Fisher Body

Detroit, MI Plant # 18 / Fleetwood in World War Two

Detroit, MI

1917-1993

This page added 1-13-2024.

Fisher Body Plant 18 was not built to make

auto bodies as were the other Fisher Body plants. It was built in

1917 at the intersection of West Fort Street and West End Street in

Detroit, MI to produce aircraft for the American entry into World War

One. This plant was the predecessor of many factories built

starting 23 years later in 1940 for the production of war goods as the

country prepared for another World War. This six-story Albert

Kahn-designed building produced approximately 2,000 out of the 4,346

deHavilland DH-4s built under license in the United States. Later,

it would become known as the Fisher Body Fleetwood plant when it began

producing the bodies for the Cadillac Fleetwood. The plant stopped

production of bodies in 1984 and was razed in 1993.

This 1918 Fisher Body-built DH-4 is on

display at the Evergreen Aviation & Space Museum in McMinnville, OR.

The DH-4 was all wood construction, as this

was the state of the art for the worldwide aviation industry during

World War One. The following photos were taken of a Dayton

Wright-built DH-4 fuselage that is on display at the Fantasy of Flight

Museum in Polk City, FL. This aircraft is awaiting restoration,

allowing visitors to view the construction methods used in World War One

aircraft. Fisher Body Fleetwood built 2,000 aircraft just like

this one.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

Author's photo.

The Fisher Body Fleetwood Plant in Detroit, MI won the Army-Navy "E"

Award four times during World War Two.

World War Two Products: B-17 exhaust collectors and engine

cowlings, B-25 exhaust collectors, B-29 exhaust collectors, XP-75

exhaust collectors and exhaust stacks,

XB-19 and XB-39 aircraft parts and assemblies; M4, M10, and M26 tank

parts; aircraft drop fuel tanks; P-80 aircraft tools; 90mm AA Guns

tools; Combat Vehicle Parts

The Fisher Body Fleetwood plant was built in

1917 to make wooden aircraft. By the time World War Two arrived

for the United States in December 1941, wooden aircraft were obsolete,

except for the DeHavilland Mosquito. By 1941, aircraft were built

using metals like aluminum and steel. Fisher Body Fleetwood

manufactured steel and aluminum components for the B-17, B-25, B-29, and

XP-75. There had been a major technology shift in the 23 years

since the end of World War One.

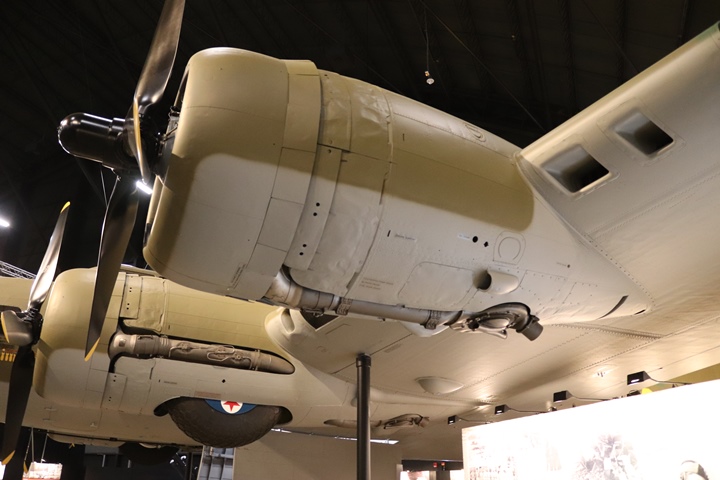

B-17 Exhaust Collectors and Engine

Cowlings:

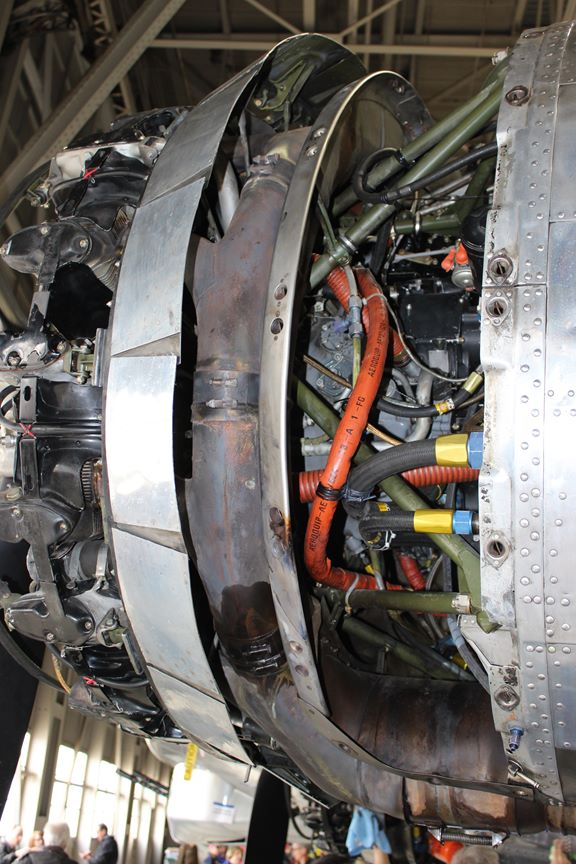

The B-17G "Yankee Lady" is being polished

for another airshow season. The cowl flaps and exhaust collectors

on this aircraft could very well have been built by the Fisher Body

Fleetwood plant which was located 22 miles to the north east of this

hangar at the Willow Run Airport in Bellevue, MI. Author's photo.

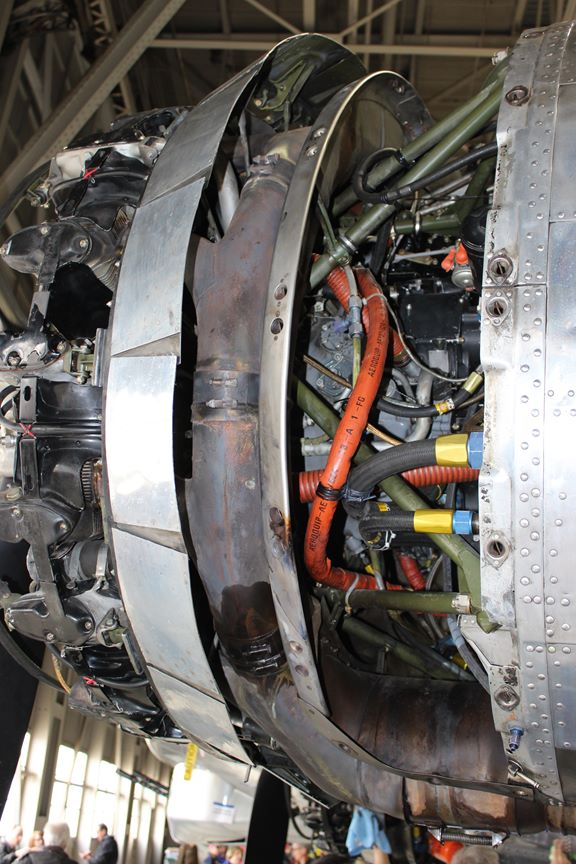

The removable portion of the engine cowl has

been removed on this engine. The cowl flaps and exhaust collector

are on the left portion of the engine. On the right portion is the

fixed portion of engine cowl. Author's photo.

This image shows the individual exhaust

collectors coming off of each cylinder. The cowl flaps can also be

seen. Author's photo.

This is a portion of a

B-17F cowl assembly being inspected at the Fleetwood plant.

Four sections of B-17 engine cowling

sections are shown in this photograph.

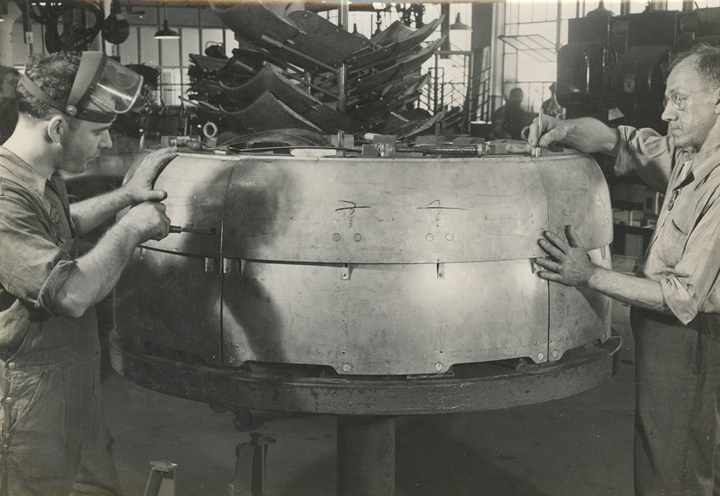

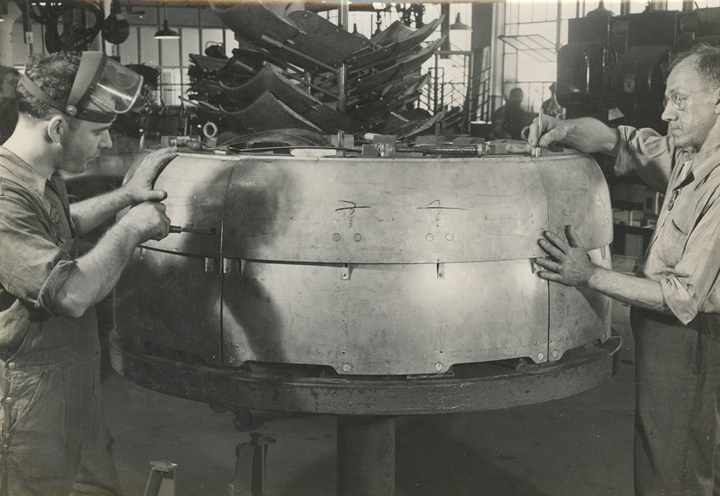

Workers are assembling a section of B-17

engine cowls.

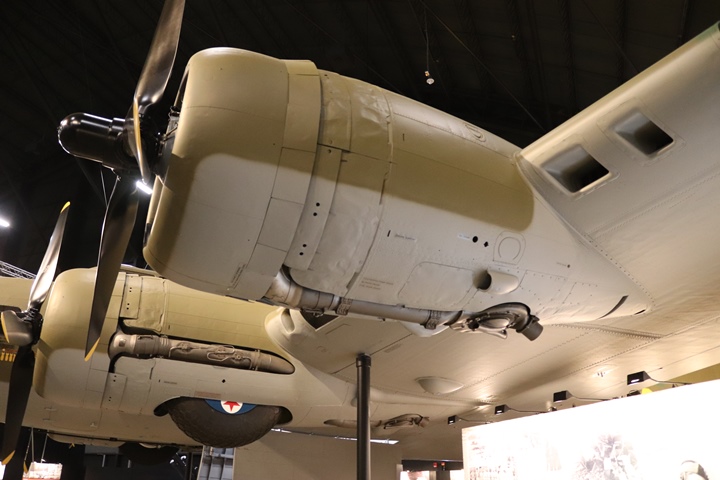

This image shows a fully cowled engine on

the B-17F "Memphis Belle." Note that the exhaust pipes on the

outboard and inboard engines are routed differently due to the landing

gear. Fisher Body Fleetwood made two different types of exhaust

collectors for the two different engines. Author's photo.

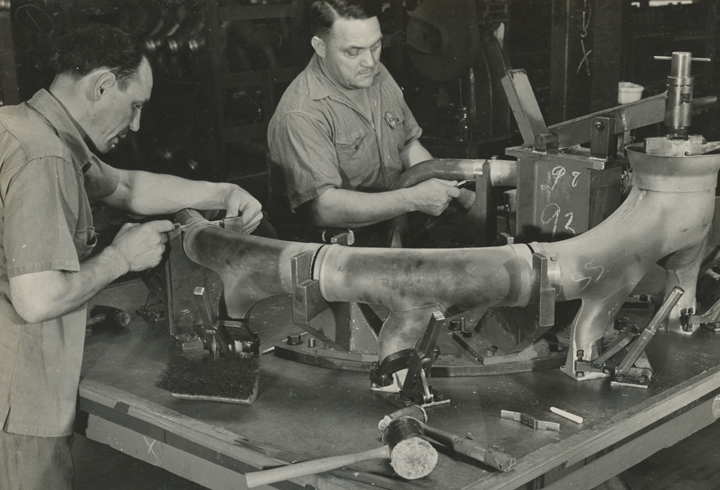

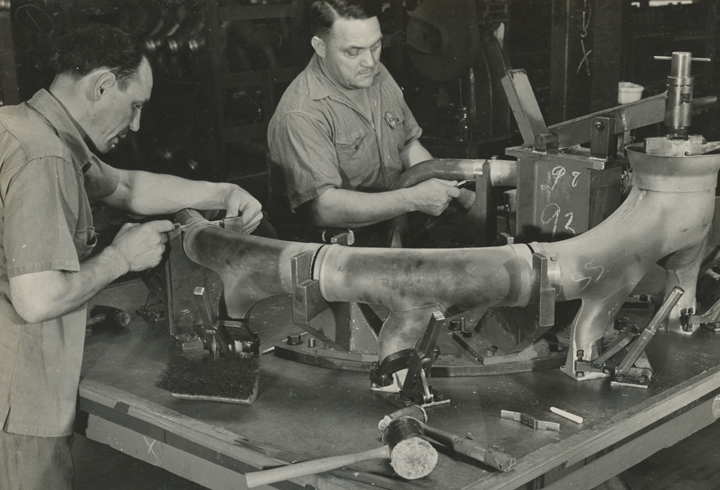

Two Fleetwood workers are using a fixture to

assemble a B-17 collector.

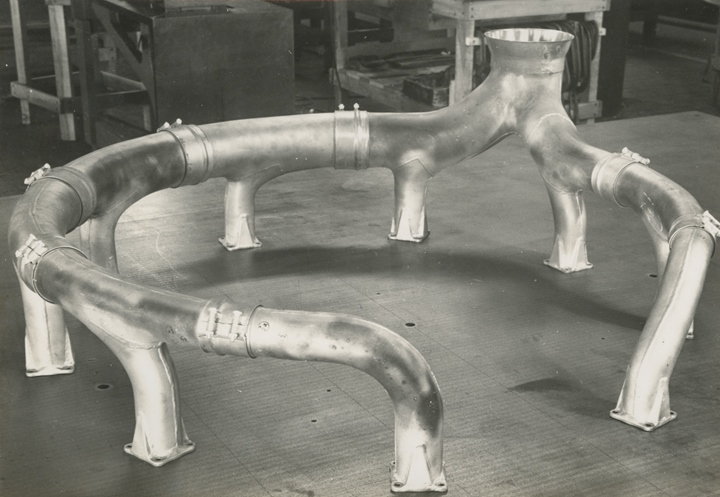

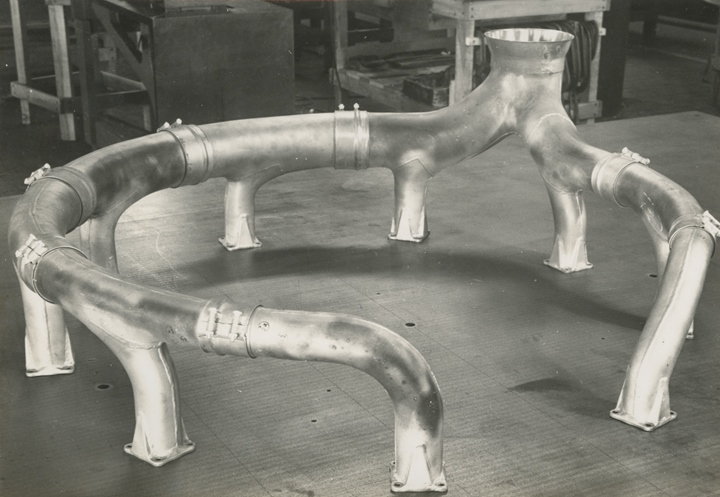

This image shows a fully assembled B-17

exhaust collector ring.

|

Table 1 -

Fisher Body Fleetwood Plant B-17 Exhaust Collector and Cowl

Assembly Production |

|

Month |

Exhaust Collectors |

Cowl Assemblies |

|

1942 |

|

|

| March

|

106 |

2 |

| April

|

135 |

39 |

| May

|

177 |

46 |

| June

|

189 |

26 |

| July

|

187 |

- |

|

August |

199 |

56 |

|

September |

146 |

317 |

|

October |

212 |

50 |

|

November |

176 |

218 |

|

December |

139 |

167 |

|

1942 Total |

1,666 |

921 |

|

1943 |

|

|

|

January |

264 |

407 |

|

February |

335 |

140 |

| March

|

306 |

290 |

| April

|

310 |

323 |

| May

|

484 |

150 |

| June

|

445 |

214 |

| July

|

320 |

482 |

|

August |

515 |

398 |

|

September |

404 |

556 |

|

October |

323 |

775 |

|

November |

369 |

640 |

|

December |

666 |

1,003 |

|

1943 Total |

4,471 |

5,378 |

|

1944 |

|

|

|

January |

331 |

923 |

|

February |

414 |

1,146 |

| March

|

520 |

1,008 |

| April

|

377 |

985 |

| May

|

496 |

876 |

| June

|

493 |

1,050 |

|

1944 Partial Total |

2,631 |

5,988 |

|

Grand

Total as of June 1944 |

8,768 |

12,287 |

The known records for Fisher Body Fleetwood's

production are only complete through June of 1944. The plant

continued to make the two products until B-17 production stopped in mid

1945.

B-29 Exhaust Collectors:

Table 2 shows the anticipated production

schedule for B-29 exhaust collectors. This schedule may well have

increased as the B-29 schedule increased as the war progressed.

Table 2-

Fleetwood B-29 Project

Exhaust Collector Scheduled Production

As of February 1944. |

|

B-29 Assembly Plant |

Boeing-Renton, WA |

Boeing-Wichita, KS |

Bell-Marietta, GA |

Martin-Omaha, NE |

Total |

|

Exhaust Collectors |

2,666 |

460 |

882 |

739 |

4,747 |

The B-29 exhaust collector was an order of

magnitude larger than that of the B-17 types. Each exhaust pipe

powered a General Electric turbo supercharger.

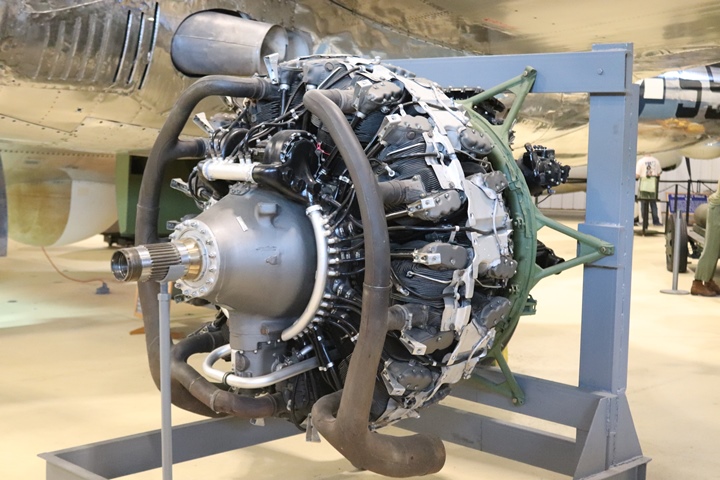

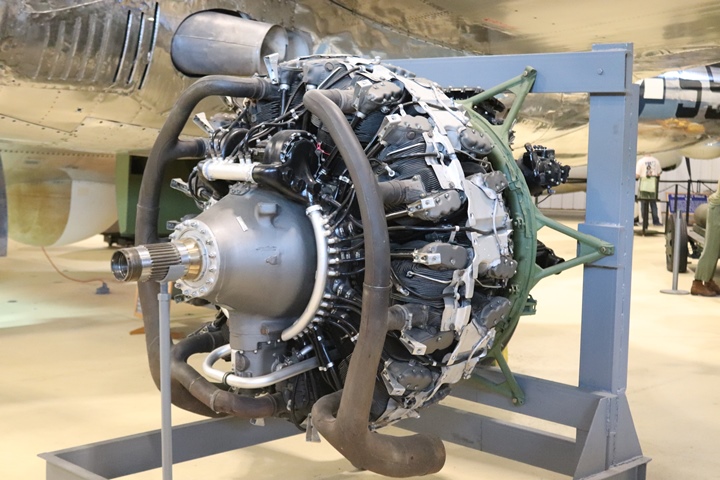

This R-3350 B-29 engine is on display at the

New England Air Museum at Windsor Locks, CT. The display has the

front exhaust collector attached to it. Each R-3350 had 18

cylinders. B-17 R-1820 engines had nine cylinders. Author's

photo.

The Museum built a special display hangar to

display its B-29 named "Jack's Revenge." Author's photo.

Author's photo.

B-25 Exhaust Collectors: Fisher

Body Fleetwood made 3,975 sets of B-25 exhaust collectors for the war

effort. Due to a shortage of the specified nickel-chromium base

alloy Inconel, the collectors were made out of stainless steel.

B-25 "Champaign Gal" is owned and operated

by the Champaign Aviation Museum, Urbana, OH. Author's photo.

The exhaust stacks on the B-25 are different

than on the B-17 and B-29. This image of the outboard side of the

port engine shows a small exhaust collector to the front and above the

exhaust outlet. The collector is not connected to all of the

cylinders. Many of them have short exhaust stacks like the two

shown at the bottom of the engine. Author's photo.

This photo shows the exhaust collector on

the outboard side of the starboard engine. Author's photo.

Shown here is the inboard side of the

starboard engine. There are four short exhaust stacks and no

collector. Author's photo.

The B-25's exhaust system contributed to it

being a very noisy aircraft for the crew. Also, because the

exhaust was not run through a turbo supercharger, this contributed to

the noise level in the aircraft. The B-25's noisy exhaust caused

many crewmen to become deaf after the war.

XP-75 and P-75 Components:

The Fisher Body Cleveland, OH Plant #2 built a handful of fighter

aircraft. In retrospect, it was one of those projects that fall

into the category of "it sounded like a good idea at the time."

Eight XP-75s and six P-75s were built using components from several

other fighter aircraft already in production to save costs. By the

time design work and tooling were completed, there were enough of other

fighters types being produced to meet the requirements of the Army Air

Forces. Therefore, the project was cancelled in late 1944.

Besides that, it wasn't that great of an aircraft. Hindsight is

always 20-20!

Fisher Body Fleetwood was assigned to furnish exhaust collectors

and stacks, reduction gear mounts, cartridge boxes, and empty shell

casing ejector chutes. Fleetwood supplied these component for the

fourteen aircraft that were built.

One Fisher P-75 Eagle still exists today

and is part of the collection of aircraft at the National Museum of the

United States Air Force in Riverside, OH. Author's photo.

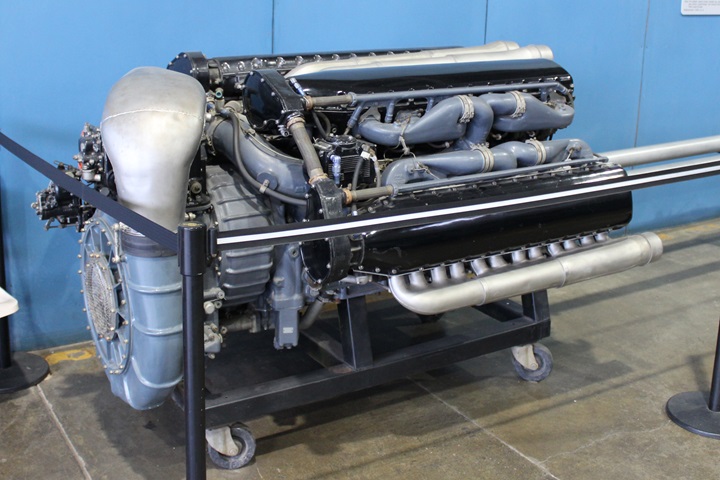

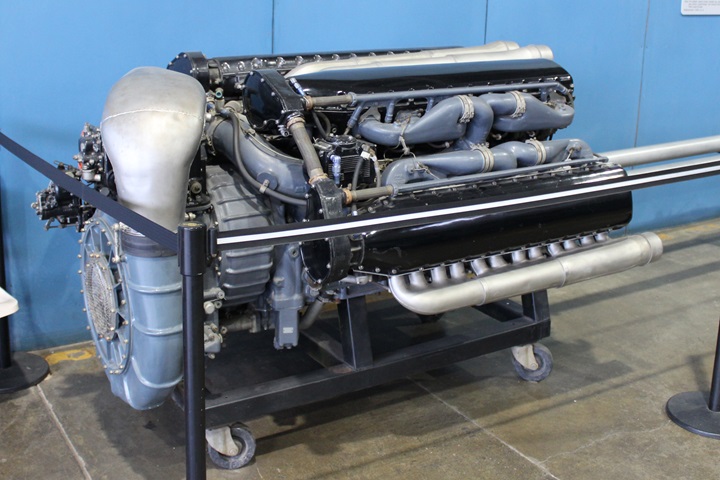

The engine of choice for the P-75 was the

Allison V-3420. Three of the four Fleetwood-produced exhaust

collectors for that engine are shown in this photo. A complete

exhaust can be seen on the side of the engine and two collector pipes

can be seen at the top. This engine is at the National Museum of

the United States Air Force. Author's photo.

Fighter Aircraft Drop Tanks:

Fisher Body Fleetwood was one of many companies that produced

disposable fuel drop tanks for both Army and Navy fighter aircraft.

The drop tanks shown here are on display at the National Museum of WWII

Aviation in Colorado Springs.

Author's photo.

Author's photo.

Tank and Tank Destroyer Components:

Fisher Body produced M4A2 and M4A3 Sherman medium tanks, M10

Wolverine tank destroyers, and M26 Pershing heavy tanks at its tank

plant in Grand Blanc, MI. Fisher Body Fleetwood produced

components for these armored vehicles. The photos below show

representative examples of each of these armored vehicles. All

were built by Fisher Body Grand Blanc.

M4A2(76) HVSS Sherman tank. Author's

photo.

M4A3(76) HVSS Sherman tank. Author's

photo.

M10 Wolverine tank destroyer. Author's

photo.

M26 Pershing heavy tank. Author's

photo.

|